Part Number: 240523

UPC Number: 633955823778

Part Number: 287933

UPC Number: 633955138315

Part Number: 119250

UPC Number: 633955058644

Part Number: 278204

UPC Number: 633955570047

Part Number: 100985

UPC Number: 633955045927

Part Number: 15E625

UPC Number: 633955037854

Part Number: 15G890

UPC Number: 633955128552

Part Number: 111040

UPC Number: 633955382473

Part Number: 15F503

UPC Number: 633955041097

Part Number: 15F498

UPC Number: 633955041059

Part Number: 15F116

UPC Number: 633955114388

Part Number: 15G584

UPC Number: 633955127227

Part Number: 116942

UPC Number: 633955793835

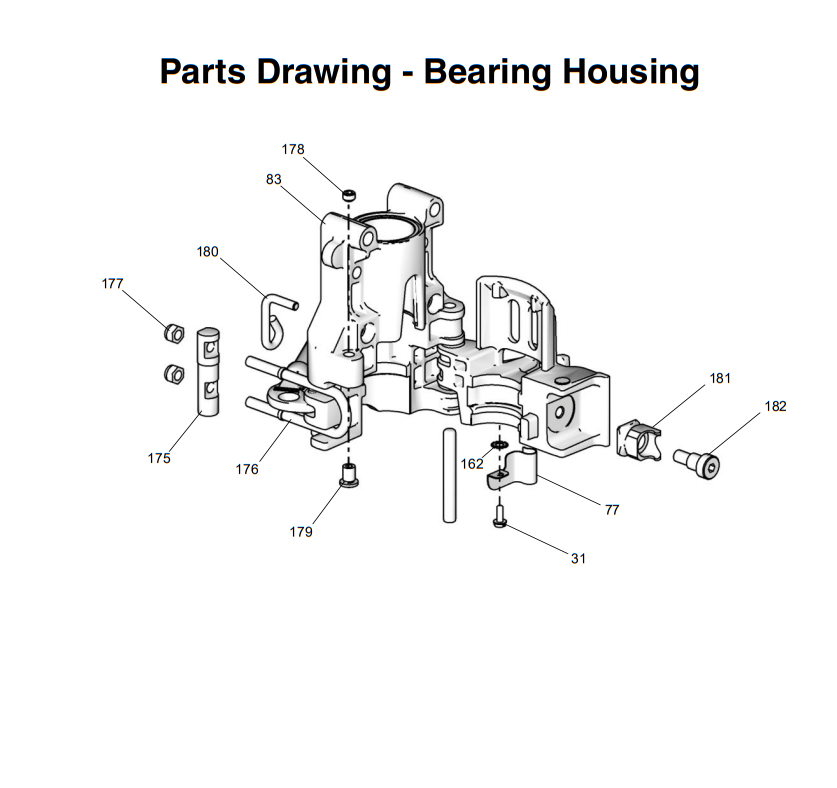

The Graco Ultra Max II 795 is a popular contractor-grade electric airless sprayer, often bundled with graco airless spray guns and graco spray tips like the RAC X series. Central to its reliability is the robust bearing housing assembly (part 240523), which supports the motor, gear train, and pump drive shaft. Worn-out bearings or damaged housings can lead to loud operation, misalignment, or premature pump failure. Understanding how the housing works—and how it fits into the sprayer—is essential for confident upkeep and parts replacement.

According to the official Ultra Max II 695/795/1095/1595 parts manual, the bearing housing (ref 83) includes the latch lever (139/140) and drain clip (77), securing the pump drive mechanism to the motor with precise alignment.

Key components included when you order the housing assembly:

Ref 83 – Bearing Housing (240523), with latch and drain clip

Ref 139/140 – Housing Latch & Pin, locking the housing securely

Ref 77 – Drain Line Clip, guides pump rod cover drain hose

Ref 162 – Lock Washer, secures latch hardware

Ref 31 – Shoulder Screws, to tighten the housing to the drive housing

This housing connects directly to the motor’s drive housing (ref 90), aligning gears and supporting the pump drive rod and cylinder.

Maintains graco sprayer parts alignment – Reduces noise and stress on the pump rod and motor gear

Protects against fluid leaks – Fluid seals sit just behind the housing

Simplifies maintenance – Latch design makes it easy to remove without disturbing pump alignment

Neglecting a worn bearing housing can lead to wobbling, lubrication failure, and strain on the graco replacement pump lower assembly (ref 91), leading to costly downtime.

Fully relieve pressure from the sprayer.

Remove pump (ref 91).

Detach front cover (ref 51) and motor shroud (ref 58).

Remove shoulder screws (ref 14) and washers (ref 12), then lift out the housing (ref 83) along with its latch (ref 140).

Inspect bearings, latch mechanism, and alignment.

Clean the mounting surfaces and lubricate gear teeth before assembly.

Fit the bearing housing into the drive housing (ref 90) and torque screws to 25–30 ft‑lb.

Secure drive housing to motor with five screws (ref 6) at 190–210 in‑lb.

Reinstall front cover and shroud, then remount the pump.

Citations provided guide torque values and order of steps.

Here’s a quick parts list frequently replaced when servicing the housing:

Bearing Housing (240523)

Latch Lever & Pin (139/140)

Drain Clip (77) & associated piped parts

Shoulder Screws (31) & Lock Washers (162) for secure attachment

Bearing Housing Kit (287933) – includes all fasteners, latches & clip.

Original paint sprayer parts ensure perfect fit and long life. Generic replacements can cause misalignment or vibration.

Check misalignment monthly – Worn bearings cause wobbling; fix early by rebuilding or swapping housings.

Lubricate gears when reinstalling – prevents dry start-up and gear wear.

Inspect the latch assembly – a loose latch can snap closed during operation, loosening housing alignment.

Tighten screws properly each time, using Graco torque specs.

Inspect sealing surfaces at shaft exit: damaged seals can lead to fluid migration and corrosion.

When replacing your graco replacement pump, inspect the bearing housing and drive coupling:

A bent pump rod or misaligned housing may cause new pump assemblies (ref 91) to leak or fail early.

Often, buyers of the ProConnect pump assembly also purchase a bearing housing kit for smoother integration.

If you need replacement parts:

The bearing housing kit (ref 83 or 287933) is available through SparyersAndParts and Graco-authorized parts stores.

If you prefer service, search “graco pump repair near me” to locate an authorized repair center that can replace both pump and housing, check alignment, and pressure-test units.

The 795 bearing housing shares many parts across Ultra Max II and related lines, allowing you to stock fewer spare parts:

The same housing, shaft seal, and latch parts are used on the 695, 795, 1095, and 1595 models.

Standard graco spray tips and RAC X switch tips fit the unified gun system, regardless of the housing used.

As part of your graco airless sprayer accessories, a bearing housing replacement supports quick gear housing swaps in field settings.

Drive housing (90) & gear components – essential for aligning bearing housing

Pump lower assembly (91) – often replaced concurrently with housing

Motor seal kit – if housing removal exposes splines or grease seals

Airless hoses, swivel fittings – check intake tube (76) and strainer (48) while the unit is apart

The bearing housing in your Graco Ultra Max II 795 is a critical structural component that ensures your graco airless spray guns operate smoothly, with stable alignment for consistent coating application. Proper care—inspection, lubrication, torque checking, and using OEM spares—extends the life of your sprayer. Paired with a quality graco replacement pump, this housing supports reliable service life and uptime.

If you face pump failure or bearing wear, upgrading both pump and housing—or seeking certified graco pump repair near me—ensures your sprayer stays a high-performance part of your graco spray equipment arsenal. With genuine paint sprayer parts and alignment checked, you’ll avoid vibration-related failures and maximize productivity.

Let me know if you'd like diagrams or part numbers for associated components, or help locating compatible graco airless sprayer accessories!

Subscribe to our newsletter to get exclusive discounts and new theme launches right in your inbox.

You may unsubscribe at any moment. For that purpose, please find our contact info in the legal notice.

![]()

![]()

![]()

![]()