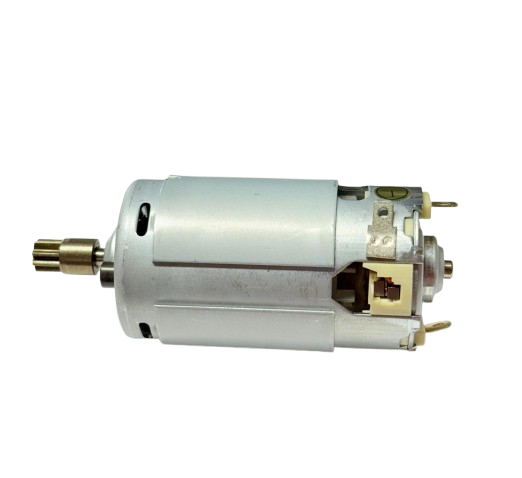

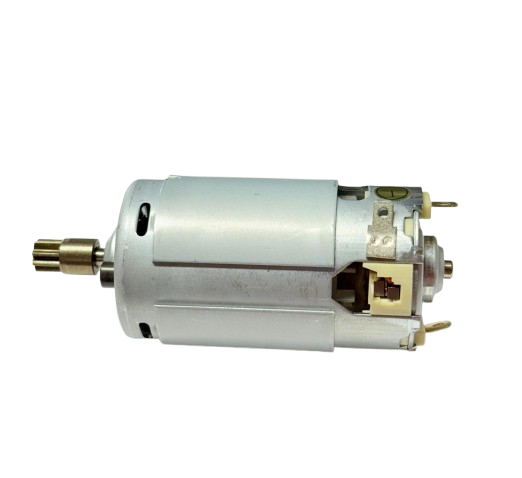

Maintain peak performance in handheld units with the Graco 17P099 Kit AC Motor. The high-efficiency AC motor core operates quietly and reduces vibration, improving comfort during extended use. Engineered for seamless integration with QuickCoupler connectors, this OEM-grade motor replacement delivers consistent power for demanding coatings applications. It ensures smooth operation with professional coatings and supports uncompromising high-pressure filtration standards, minimizing the risk of clogs and downtime. Whether you’re working with an airless sprayer, it delivers reliable output.

Crafted by Graco to meet rigorous standards, installation is quick and straightforward, with detailed instructions guiding you through every step. The robust AC motor core resists wear from abrasive coatings and high-pressure cycling, ensuring longer service intervals and more uptime. Combined with genuine Graco parts such as o-rings and mesh filters, this replacement kit enhances the lifespan of your system and maintains peak atomization quality, delivering smooth spray patterns even with heavy-bodied materials.

Graco 17P099 Kit AC Motor offers an exceptional blend of reliability and power for industrial and professional painting operations. Designed to replace worn or defective motor assemblies, this kit delivers consistent torque and smooth operation across a range of demanding environments. Precision winding and balanced components minimize vibration, reducing wear on pump assemblies and prolonging service intervals. Compatible with multiple Graco units, this upgrade facilitates a restoration of factory-spec performance with minimal downtime. Installation remains straightforward even for those with limited mechanical experience.

Featuring a robust design with sealed bearings and a durable end shield, equipment longevity receives a significant boost. Advanced epoxy encapsulation protects windings from chemical exposure, making it ideal for solvent-based coatings. Its thermal protection system guards against overheating during extended tasks, ensuring uninterrupted spraying at variable flow rates. End shields also incorporate labyrinth seals to prevent dust intrusion, extending operational life in abrasive settings. Users can expect a quieter operation compared to generic aftermarket replacements, leading to less fatigue and clearer communication on busy job sites.

Maintenance departments often pair this kit with the graco 395 airless paint sprayer to maximize uptime in high-pressure environments. The kit’s standardized mounting flange and shaft diameter eliminate the need for custom adapters, so retrofits happen quickly. Torque output remains stable across a wide voltage range, safeguarding flow consistency even under fluctuating electrical conditions. A sealed conduit connector further enhances protection from moisture and particulate ingress, preserving the internal windings and preventing early-stage breakdowns in harsh jobsite conditions.

Catering to efficiency-minded professionals, motor windings utilize copper-grade magnetic lamination to minimize eddy current losses. At full load, efficiency peaks at over 85%, reducing electrical losses and lowering operating costs. End-users notice lower current draw during continuous spray sessions, which diminishes heat buildup within the stator assembly. Vibration metrics remain within tight tolerances, enabling smoother reciprocation within pump assemblies and reducing maintenance frequency. Whether tackling residential projects or massive commercial coatings, users report uniform atomization and repeatable results in challenging climates.

Engineers appreciate how this kit complements systems like the graco 490 paint sprayer, maintaining recommended spray pressures without noticeable power drop-offs. Integration into existing manifolds and pressure regulators is seamless thanks to strict adherence to original equipment specifications. Improved heat dissipation across the stator assembly allows longer run times between service check-ups, making it ideal for multi-gallon finishing jobs. Rigorous quality control processes accompany every production batch, with dynamometer testing ensuring each motor meets specified torque and speed curves under simulated load.

Material compatibility remains an essential consideration, and this kit aligns perfectly with high-viscosity coatings used in heavy corrosion protection. Housing materials include anodized aluminum alloys that resist acid-based primers and epoxy coatings, ensuring durability in shipyards and offshore structures. Field technicians often install it alongside a graco 695 paint sprayer for demanding industrial lines. Protective coatings on the housing resist solvent attacks and prevent rust even under harsh environmental exposure. Quick-connect fittings and an integrated thermal cutout provide extra layers of security, guarding against overcurrent scenarios.

Installation demands only a few basic hand tools and follows a straightforward manual. Align the motor shaft with the pump coupling, then secure the flange bolts to specified torque values using a calibrated torque wrench. Maintenance teams should apply a light coating of high-temperature grease to the bearings every 500 hours of operation, as outlined in the service guide. Always verify voltage parameters before startup and confirm the phasing sequence in three-phase applications to prevent reversed rotation. After alignment, perform a brief run-in at low speed, monitoring temperature and current draw carefully.

Backed by factory-engineered specifications and supported by comprehensive service manuals, this motor kit addresses the needs of professional contractors and fleet managers alike. For detailed troubleshooting information, wiring schematics, and authorized replacement part listings, consult the official service manual or contact certified technical support. In-depth diagnostics and exploded diagrams streamline part identification, while regular firmware checks on control modules help align motor performance with pump calibration. Authorized training seminars and field service support further enhance maintenance proficiency for facility technicians.

Subscribe to our newsletter to get exclusive discounts and new theme launches right in your inbox.

You may unsubscribe at any moment. For that purpose, please find our contact info in the legal notice.

![]()

![]()

![]()

![]()