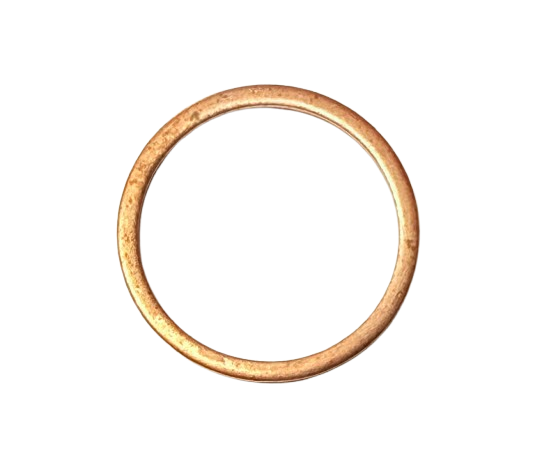

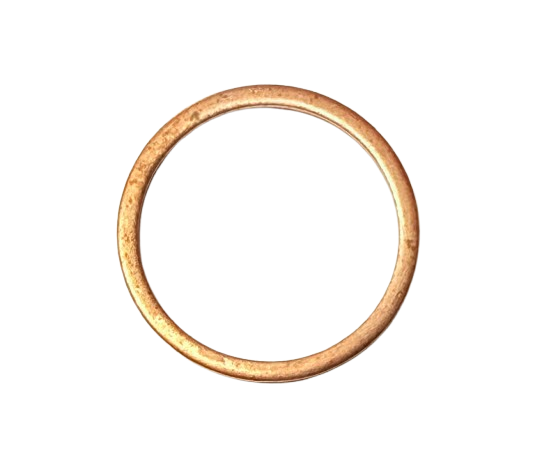

The Graco 150429 Metallic Gasket delivers a precision-engineered seal that ensures peak performance in demanding industrial applications. Crafted from robust stainless steel alloy, this shaft seal kit provides exceptional durability and chemical resistance. Ideal for use with a wide range of equipment, it maintains consistent pressure and prevents leaks under extreme conditions. Optimize maintenance cycles and extend the service life of your pumping systems with the reliability expected from Graco. Harness the airless sprayer for flawless finishes.

Designed for demanding high-pressure filtration tasks, the Metallic Gasket 150429 integrates seamlessly into Graco spray systems. Its precision tolerances reduce downtime and support consistent spray patterns when applying professional coatings. The durable construction withstands abrasive particles and extreme temperatures, making it a reliable choice for industrial finishing operations. Trust the gasket to maintain optimal performance and protect your equipment investment.

$12.73Engineered for demanding industrial fluid handling, the Graco 150429 Metallic Gasket is a high-precision sealing solution designed to maintain optimum pump integrity under extreme operating conditions. Manufactured from stainless steel alloys with specialized surface treatments, this metallic seal offers exceptional resistance to abrasive media and thermal fluctuations. Its compact geometry and low-profile cross-sectional design ensure compatibility with a broad range of rotating shafts, enabling seamless integration into existing pump frames without the need for extensive modifications. With a resilience rating exceeding six thousand hours in continuous duty cycles, the Graco gasket delivers unparalleled performance in both centrifugal and positive displacement pump systems. A key advantage of this component is its capacity to sustain consistent pump efficiency at pressures up to 3,000 psi, making it ideal for high-pressure filtration applications where seal longevity is critical. Typical installation tolerances are maintained within ±0.005 mm radial clearance, ensuring minimal leakage rates below 0.02 L/min per seal face. The gasket’s robust design features CNC-machined seal faces with a Ra surface finish of 0.2 µm or better, effectively reducing friction and wear. A specialized heat treatment process enhances grain boundary strength, providing superior performance in corrosive environments and under repetitive thermal cycling up to 300 °C. These properties collectively contribute to reduced downtime, simplified maintenance schedules, and improved overall system reliability.

In applications such as automated airless sprayer systems, this gasket assembly is crucial for maintaining consistent fluid pressure and preventing backflow. The sealing element operates effectively across a broad viscosity range, from low-viscosity solvents to high-solids coatings, and adapts dynamically to pressure fluctuations without compromising structural integrity. The design also facilitates rapid assembly and disassembly, reducing service intervals and enabling swift component replacement in field conditions. Featuring an innovative dual-lip configuration, the shaft seal concentrates contact pressure at critical points to minimize wear and prolong service life. Incorporating advanced polymer encapsulation around the metallic core further dampens vibrational forces transmitted through the pump housing, enhancing overall system stability. Operating at temperatures from –20 °C to +180 °C, the Graco component supports complex fluid dynamics encountered in professional coatings delivery lines, where consistent atomization and spray patterns are essential.

Within high-pressure filtration and chemical injection systems, the gasket’s metallic-to-metallic interface ensures a leak-proof seal capable of withstanding differential pressures up to 3,000 psi without deformation. Performance metrics derived from accelerated life testing indicate less than 2 % variance in sealing torque after 10 million shaft revolutions. Finite element analysis (FEA) simulations confirm uniform stress distribution across the seal face during peak operational loads, reducing the risk of stress concentration and fatigue failures. Additionally, the low-friction coefficient surface treatment enhances pump efficiency by minimizing mechanical drag, contributing to energy savings and reduced operational costs. Engineers leverage this component as a standard upgrade in high-flow rate pumps used for water treatment, petrochemical transfer, and abrasive slurry pumping. By selecting the metallic gasket, system architects can ensure compliance with industry standards such as API 682 and ISO 21049 for mechanical seals. Integration with advanced monitoring sensors permits real-time diagnostics of seal performance, allowing proactive maintenance and further extending mean time between failures.

To maximize seal longevity, it is recommended to install the gasket with uniform axial preload, employing calibrated torque tools to achieve the manufacturer-specified clamping force. Surface grooves on the gland plate should be cleaned and inspected for burrs to prevent localized wear on the gasket surface. Periodic visual inspections, complemented by non-invasive leak detection methods, allow maintenance teams to predict end-of-life cycles before catastrophic failure. When replacing worn components, ensure that mating surfaces are free of contaminants and that alignment tolerances are within prescribed limits to avoid eccentric loading. For operations involving highly abrasive media, supplement the metallic gasket with a sacrificial wear ring to absorb particulate impacts and extend service intervals. These best practices, when implemented alongside regular system diagnostics and lubrication protocols, deliver optimal uptime and uphold rigorous operational standards in demanding industrial environments. Routine performance audits leveraging vibration analysis and thermographic scanning further enhance predictive maintenance strategies, safeguarding critical infrastructure against unplanned downtime. Integration of this seal into modular pump systems also supports rapid retrofit and reduces engineering hours during system upgrades.

Subscribe to our newsletter to get exclusive discounts and new theme launches right in your inbox.

You may unsubscribe at any moment. For that purpose, please find our contact info in the legal notice.

![]()

![]()

![]()

![]()