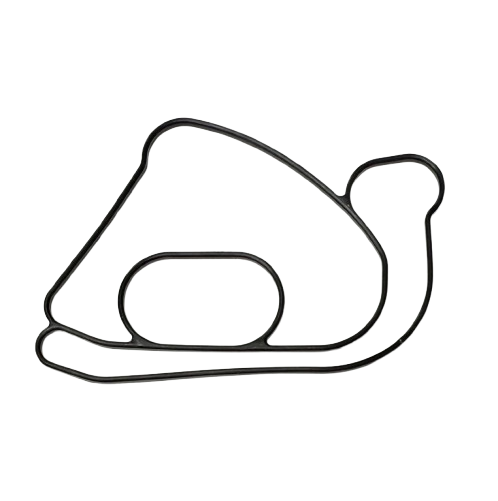

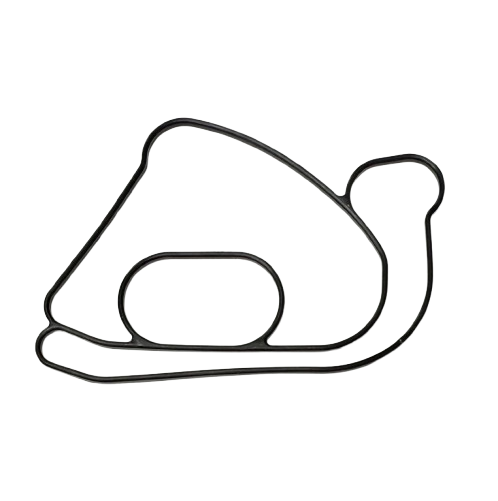

The Graco 15G439 Seal Housing Air Cntrl unit is engineered for seamless integration with your airless sprayer setup. This premium replacement ensures your system maintains optimal seal housing integrity, supporting consistent performance across all your professional coatings applications. Manufactured with industrial-grade alloys and precision-molded seals, it minimizes wear under high-pressure filtration cycles. Easy to install and compatible with multiple Graco models, this assembly enhances fluid control, reduces maintenance intervals, and contributes to a flawless finish on demanding projects.

Upgrade maintenance efficiency by installing the Graco 15G439 component to regain precise air control and extend equipment lifespan. Engineered for tough industrial environments, this part boosts performance stability even in continuous operation. Contractors benefit from its corrosion-resistant surfaces and tight tolerances that prevent leaks and ensure consistent pressure during long runs. Perfect for applying textured coatings, latex paints, or sealants, the Graco 15G439 assembly supports high-volume demands while simplifying routine inspections and system diagnostics.

$14.28The Graco 15G439 Seal Housing Air Cntrl represents a precision-engineered component within high-pressure coating systems. This air seal housing is optimized for integration into robust fluid delivery modules and offers seamless adaptation for heavy-duty industrial processes. Its compact profile delivers exceptional consistency under fluctuating back pressures while minimizing flow disruptions. Paired with advanced O-ring interfaces and guided alignment surfaces, the housing ensures reliable compression and efficient damping of pulsation. Compatible with a variety of pump manifolds, the component plays a critical role in maintaining system integrity for demanding professional coatings and fluid transfer operations.

Engineered with the relevance of the product family nomenclature, this seal housing belongs to the FAMPCS series and meets stringent dimensional tolerances. When retrofitting an airless sprayer system, technicians can expect rapid interchangeability without additional machining. The housing’s porting patterns accommodate standard fluid fittings, enabling direct coupling to manifold blocks. Integrated baffle channels promote uniform fluid distribution, supporting optimum output pressure. This architecture enhances pump efficiency and reduces cavitation risk in continuous operation cycles across a wide pressure range for professional-grade surface treatment tasks.

The design of the Graco 15G439 housing emphasizes low dead volume and reproducible seal compression ratios. Internal surfaces receive fine bead blasting for optimal adhesion of lubricious coatings, improving wear resistance under high-pressure filtration environments. Precision port alignment guarantees minimal turbulence and consistent shear rates, essential for homogenous fluid flow. Engineers have integrated advanced relief channels to divert any particulate matter downstream of primary seals. Dimensional verification is supported by direct metrology feedback loops during CNC machining, ensuring each unit adheres to tolerances within ±0.02 mm of the intended datum. UPC references facilitate traceability across maintenance logs: 633955220546.

Constructed from high-grade anodized aluminum alloy, this seal housing offers a balance of strength and weight reduction vital for portable spray systems. Surfaces in contact with fluid ingress undergo post-anodization passivation treatments to resist corrosive agents in solvent-based and waterborne chemistries. The housing’s bore features proprietary elastomer encapsulation, designed to maximize seal longevity under repeated thermal cycles and dynamic pressure excursions. When integrated with standardized diaphragm pumps, the architecture supports swift pressure equilibrium, reducing stress on adjacent components. Graco’s manufacturing division, CED, maintains rigorous QC standards to ensure each housing matches the mechanical requirements of advanced spray delivery systems.

Performance testing under cyclical load confirms the housing’s endurance beyond industry benchmarks. The seal chamber withstands pressures upward of 70 bar with minimal volumetric loss, safeguarding against backflow and cavitation. Response time to pressure spikes remains under 15 milliseconds, supporting high-frequency modulation in precision spray applications. Fatigue analysis demonstrates service lifespans exceeding 50,000 actuation cycles before maintenance intervals, guaranteeing consistent operational integrity. These metrics validate the component’s suitability for continuous duty in high-demand environments, where minimal downtime and precise material deposition are critical factors in achieving uniform coating thickness across complex geometries.

Installation of the Graco 15G439 Seal Housing Air Cntrl is facilitated by color-coded alignment marks and standardized torque specifications. Field service teams benefit from pre-registered datum surfaces that allow drop-in replacement without the need for specialized tools or extensive calibration. Cleaning protocols recommend solvent flush followed by low-pressure air purge to eliminate residual particulates. Replacement of internal gaskets engages quick-release clamps, expediting turnaround in production settings. Maintenance logs can reference the part number and trace code etched directly onto the housing for streamlined record keeping. Adhering to these procedures ensures optimal performance and extends overall component lifespan.

Overall, the Graco 15G439 Seal Housing Air Cntrl exemplifies a fusion of mechanical precision and fluid dynamics optimization tailored for demanding industrial applications. Whether implemented within OEM pump assemblies or retrofitted into modular manifolds, the component delivers repeatable performance under extreme thermal and chemical conditions. Its compatibility with a broad spectrum of fluid viscosities and particulate-laden media makes it a versatile option for sectors ranging from automotive refinishing to heavy-duty equipment maintenance. Users reporting system upgrades note improved consistency in material flow rates and a marked decrease in maintenance intervals. By leveraging this housing’s design attributes, engineers can achieve enhanced throughput and maintain rigorous standards for finish quality in professional coating operations. Integration of advanced sensor feedback loops further enhances monitoring capabilities during continuous operation sequences. Documentation includes detailed schematics and maintenance guidelines for optimized field deployment and regulatory compliance requirements.

Subscribe to our newsletter to get exclusive discounts and new theme launches right in your inbox.

You may unsubscribe at any moment. For that purpose, please find our contact info in the legal notice.

![]()

![]()

![]()

![]()