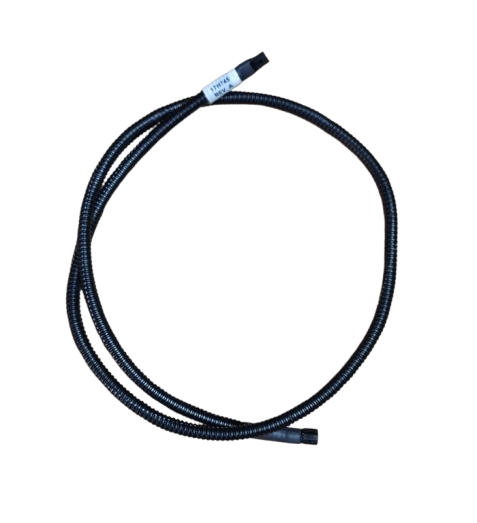

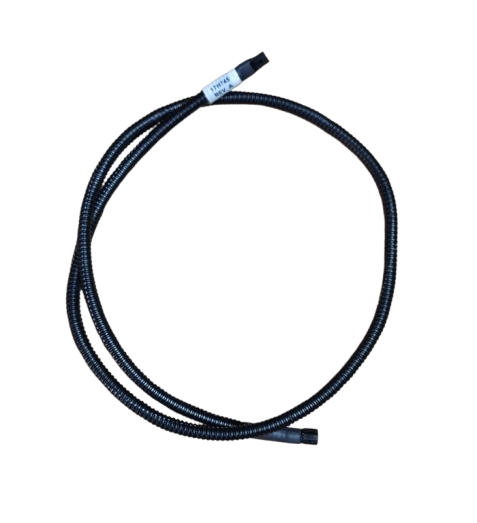

Optimize your finishing setup with the Graco 17H745 Conductor, Electrical Jumper Assembly. This essential component delivers reliable electrical connectivity for airless sprayer performance, ensuring seamless operation under demanding conditions. Engineered for precision, its robust construction maintains stable voltage paths across your sprayer network, supporting consistent delivery of professional coatings and reducing downtime. With high-pressure filtration systems in place, this jumper assembly stands up to rigorous use, streamlining maintenance checks and boosting overall efficiency. The compact design integrates effortlessly into existing setups, making it a versatile addition for contractors and industrial finishing teams. Precision-engineered connectors resist corrosion and abrasion, extending service life even in harsh jobsite environments. Intuitive latch mechanisms simplify attachment and removal, reducing setup times. Whether tackling large-scale industrial coating applications or detailed architectural finishes, this assembly enhances system performance and reliability. Field-proven in rigorous testing, it supports uninterrupted sprayer cycles, offering professionals a dependable solution for optimized workflow and superior finish quality.

Graco 17H745 Conductor and its companion Electrical Jumper Assembly serve as critical harness components in high-pressure fluid delivery systems. Precision-machined contacts ensure uninterrupted power and signal transfer between pump modules, control panels, and external power sources. Rugged insulation jackets guard against abrasion, moisture penetration, and chemical exposure typical of construction or industrial environments. Symmetrical connector shells accurately align male and female terminals, minimizing insertion force and ensuring consistent electrical continuity. This assembly plays a pivotal role in maintaining uptime and extending equipment lifespan across demanding spray-, coating-, and lubrication-based applications.

Harness wires are sized to match ampacity requirements precisely, balancing current-carrying capacity with flexibility. Multi-strand conductors use tinned copper to resist corrosion while preserving conductivity under vibration and flex. Insulation compounds are rated for wide temperature ranges, from freezing job sites to hot fluid streams. Connector housings employ high-performance polymers optimized for UV, impact, and solvent resistance. Compliance with industry standards like UL, CE, and RoHS provides peace of mind for system integrators and service technicians overseeing demanding maintenance schedules.

High-purity copper core reduces dielectric losses and voltage drop over extended conductor lengths. Dual-layer plating—nickel undercoat with gold or silver overlay—ensures low contact resistance even after repeated mating cycles. Overmolded strain reliefs and integrated cable clamps distribute stress evenly and prevent conductor fatigue. Sheath materials such as polyurethane or PVC deliver abrasion and oil resistance while maintaining flexibility. Compact connector footprints facilitate routing through confined spaces, and keyed shells eliminate misalignment risks during field assembly.

Engineers can rely on tightly controlled impedance values to support both power delivery and data communication channels. Threaded coupling rings and bayonet locks secure connectors against vibration-induced loosening. Shielding layers and grounded shells suppress electromagnetic interference, safeguarding sensitive control circuits. Available colors and pin-count options allow customization for diverse pump configurations. Integration with graco pump repair kits simplifies on-site replacement, enabling technicians to swap harness units without specialized tools or lengthy downtime.

Pre-assembled pigtails include factory-applied labels and color codes, streamlining identification during installation. Snap-in latches and quick-release collars accelerate coupling, reducing labor hours on crowded equipment racks. Compatible with standard conduit fittings and cable glands, connectors can interface with existing panels or enclosures effortlessly. Field-focused instructions and clear torque specifications ensure consistent assembly quality. Maintenance crews working alongside graco texture guns and other application equipment will appreciate the intuitive plug-and-play design.

Regular inspection intervals can be scheduled without full system shutdown: partial disconnection of the jumper assembly leaves core functionality intact. Replacement harnesses ship with certification test reports and traceable lot numbers, meeting stringent quality auditing requirements. Spares can be stored in modular service kits to reduce inventory complexity. When paired with an authorized graco sprayer repair kit, this conductor assembly integrates seamlessly into a comprehensive parts strategy, simplifying everything from diagnostics to full system refurbishment.

Operational leaders and field technicians seeking to optimize performance will find this jumper assembly indispensable. Comprehensive documentation includes wiring diagrams, torque values, and environmental ratings for rapid integration. Recommended preventive maintenance practices, combined with periodic contact inspections, guarantee prolonged conductivity and mechanical integrity. For tailored customization or expedited delivery of specialized harness assemblies, reach out to our authorized service center for expert guidance and technical support.

Subscribe to our newsletter to get exclusive discounts and new theme launches right in your inbox.

You may unsubscribe at any moment. For that purpose, please find our contact info in the legal notice.

![]()

![]()

![]()

![]()