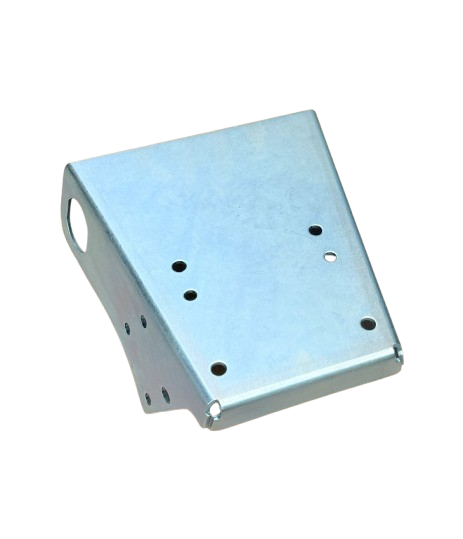

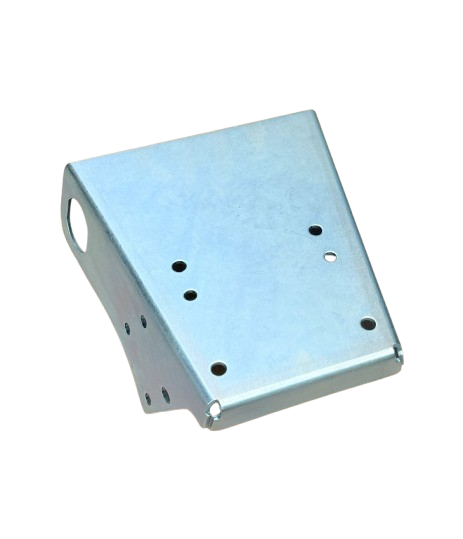

The Graco 17G328 Motor Mount Plate is a genuine OEM part that ensures secure motor attachment, reducing vibration and maintaining proper alignment for 340E pump systems.

The Graco 17G328 Motor Mount Plate is a genuine OEM component designed to securely attach the motor to Graco pump assemblies, ensuring stability, alignment, and vibration-free operation.

This motor mount plate is essential for maintaining proper motor alignment and reliable pump performance in demanding applications.

The Graco 17G328 Motor Mount Plate is manufactured to OEM standards to ensure a secure fit between the motor and pump assembly. It reduces vibration, maintains proper alignment, and supports consistent and efficient operation in professional and industrial Graco pump systems.

| Specification | Details |

|---|---|

| Part Number | 17G328 |

| Component Type | Motor Mount Plate |

| Application | Secures motor to pump assembly |

| Compatible Pump Series | 340E Pump Systems |

| Manufacturer | Graco (OEM) |

The Graco 17G328 Motor Mount Plate is an OEM component that securely attaches the motor to 340E pump systems, reducing vibration and ensuring proper alignment.

Subscribe to our newsletter to get exclusive discounts and new theme launches right in your inbox.

You may unsubscribe at any moment. For that purpose, please find our contact info in the legal notice.

![]()

![]()

![]()

![]()