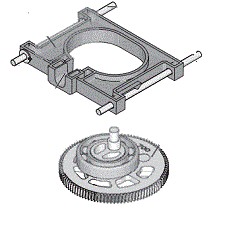

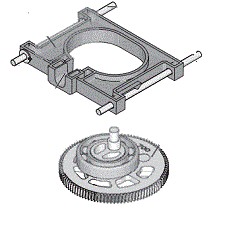

The Graco 17J869 Gear Kit 820 is a genuine OEM replacement for smooth pump operation and long-lasting performance in airless sprayers.

The Graco 17J869 Gear Kit 820 is a genuine OEM replacement part designed for Graco airless sprayers. It provides reliable gear performance, ensuring smooth pump operation and extended equipment life for professional painting and coating applications.

| OEM Part Number | 17J869 |

|---|---|

| Product Type | Gear Kit 820 |

| Compatible Equipment | Graco ProXChange 820, ProXChange 830, Mark V |

| Application | Airless paint sprayer pump repair and maintenance |

Subscribe to our newsletter to get exclusive discounts and new theme launches right in your inbox.

You may unsubscribe at any moment. For that purpose, please find our contact info in the legal notice.

![]()

![]()

![]()

![]()