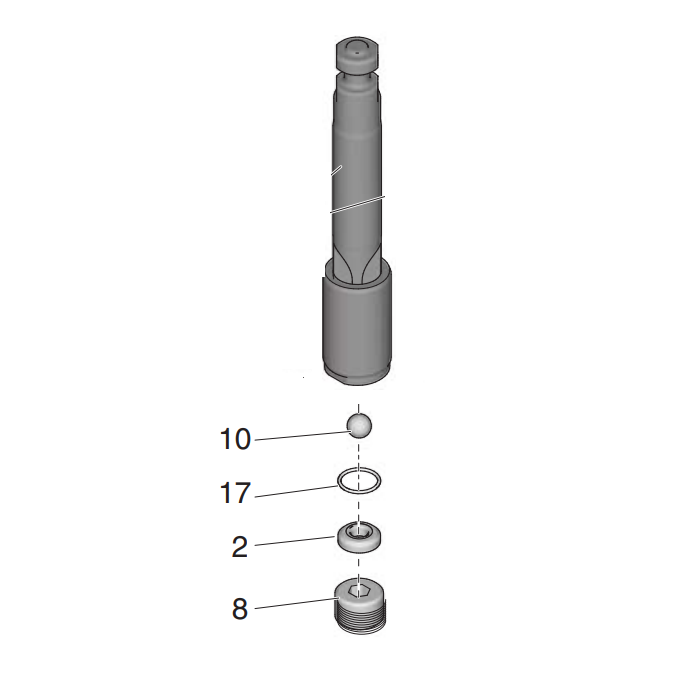

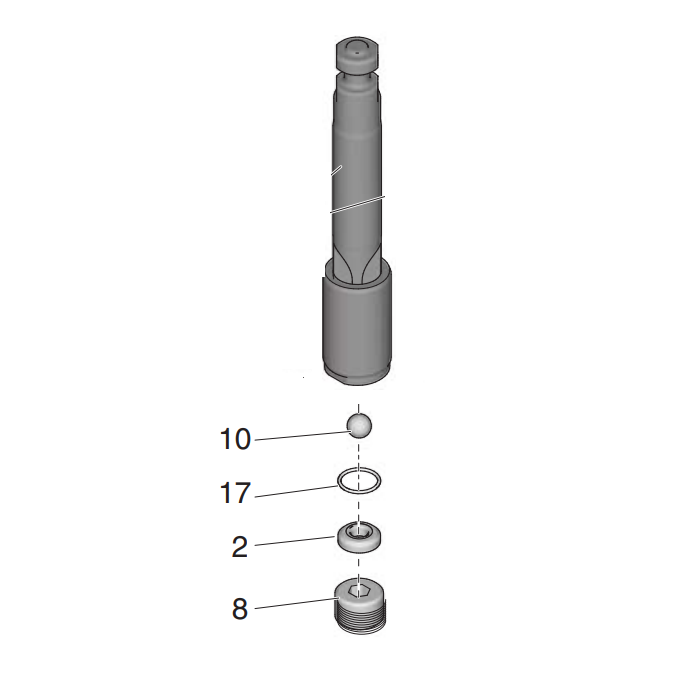

Genuine OEM replacement designed to restore smooth pumping action and consistent pressure in compatible Graco airless sprayers.

The Graco 17K692 Piston Rod Assembly is a genuine OEM replacement part engineered to restore smooth pump operation and consistent pressure in compatible Graco airless paint sprayers. Manufactured from hardened steel, it delivers long-lasting durability and reliable performance in professional and heavy-duty applications.

| Graco Sprayer Model | Compatibility Details |

|---|---|

| Graco 390 PC | Models equipped with the ProConnect Express pump |

| Graco Ultra 395 PC | Uses 17J552 Express fluid pump |

| Graco Ultra Max II 490 PC Pro | Compatible with Express pump configurations |

| Graco Ultra Max II 495 PC Pro | Direct-fit when equipped with 17J552 pump |

| Graco Ultra Max II 595 PC Pro | Newer models using Express pump system |

| Graco FinishPro II 395 PC | ProConnect Express pump design |

| Graco FinishPro II 595 PC Pro | Compatible Express pump application |

Choosing a genuine Graco 17K692 Piston Rod Assembly ensures proper fit, dependable performance, and extended service life. OEM parts help reduce downtime, maintain spray consistency, and protect the integrity of your pump system.

Subscribe to our newsletter to get exclusive discounts and new theme launches right in your inbox.

You may unsubscribe at any moment. For that purpose, please find our contact info in the legal notice.

![]()

![]()

![]()

![]()