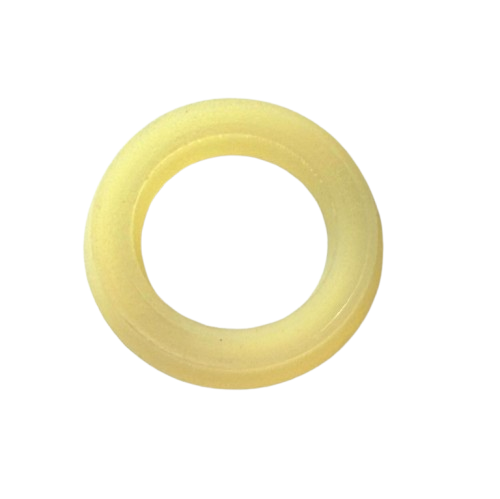

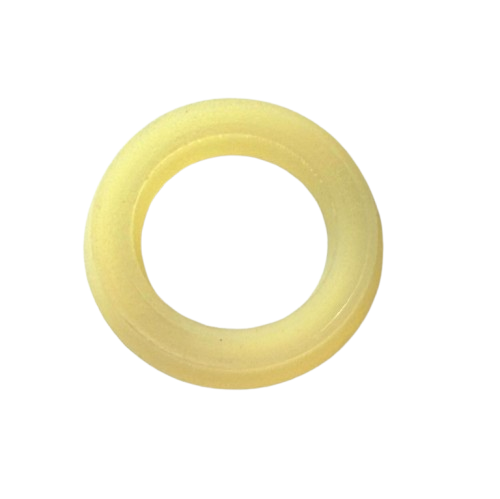

The Graco 105522 U-Cup Seal ensures a tight, leak-free seal for consistent spray performance in Graco airless sprayers.

The Graco 105522 U-Cup Seal is a high-performance polyurethane piston seal designed for use in airless paint sprayers and pump assemblies. It ensures tight sealing between the piston and cylinder, preventing fluid leakage and maintaining consistent spray pressure. This seal is a critical part of the fluid section in several Graco airless sprayers and delivers long-lasting durability under demanding use.

Below is a list of Graco machines and sprayer models that use the 105522 U-Cup Seal as part of their displacement pump or fluid section:

| Specification | Details |

|---|---|

| Part Number | 105522 |

| Material | Polyurethane |

| Type | U-Cup Seal |

| Compatibility | Fits various Graco airless paint sprayers (see list above) |

| Common Use | Displacement pump / fluid section sealing |

The Graco 105522 U-Cup Seal often pairs with backup washer part 186-652 (replaced by 196-759) in pump rebuild kits. Always confirm compatibility using your sprayer’s parts manual to ensure correct installation and performance.

Subscribe to our newsletter to get exclusive discounts and new theme launches right in your inbox.

You may unsubscribe at any moment. For that purpose, please find our contact info in the legal notice.

![]()

![]()

![]()

![]()