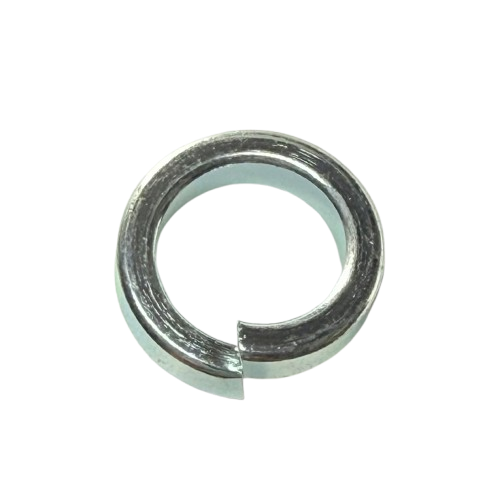

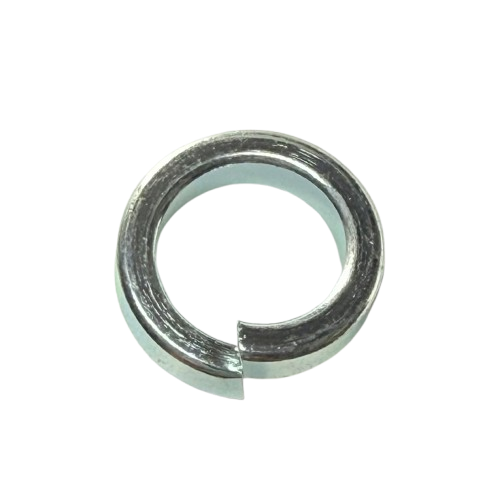

Maintain secure fastener connections with the Graco 106115 Hi‑Collar Lock Spring Washer, designed for high‑cycle spray system assemblies.

The Graco 106115 Lock Spring Washer (Hi‑Collar) is a specialized locking component engineered to retain critical internal fasteners under high‑vibration, high‑cycle spray‑equipment conditions. Its high‑collar design provides superior grip and resistance to loosening, ensuring maintenance‑free reliability in demanding spray systems.

| Height (Collar) | Approx. 0.25 in |

|---|---|

| Width / Length | Approx. 0.45 in × 0.45 in |

| Material | Hardened steel spring washer |

| Finish | Protective plating to resist corrosion |

| Function | Locking washer with high‑collar geometry to prevent fastener loosening |

This hi‑collar lock spring washer is built to stabilize fastening systems under intense cyclical loading. The elevated collar ensures increased surface engagement, enhanced contact with mating components and improved resistance to axial displacement and loosening due to vibration.

Installed in critical clamp assemblies and drive housings of high‑output sprayers, this washer maintains preload, avoids fastener backlash and contributes to overall system integrity. Using the 106115 washer helps extend service intervals and supports consistent equipment performance.

Replace the washer any time the associated fastener is serviced or removed. Ensure the mating surface is clean and flat before installation. Torque the fastener to the specification recommended by the equipment manual, and verify that the collar seats fully. Inspect at regular service intervals for wear or deformation—replace if the collar is flattened or lost its spring‑action.

Manufactured under stringent production controls, each washer undergoes dimensional verification, hardness testing and corrosion screening. Compatibility with Graco’s high‑cycle spray systems ensures OEM‑level performance and fit.

Subscribe to our newsletter to get exclusive discounts and new theme launches right in your inbox.

You may unsubscribe at any moment. For that purpose, please find our contact info in the legal notice.

![]()

![]()

![]()

![]()