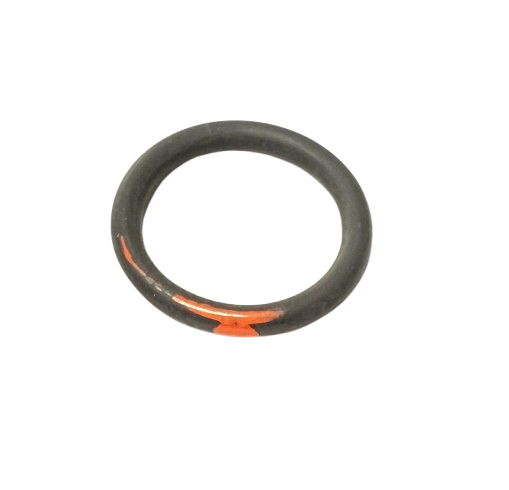

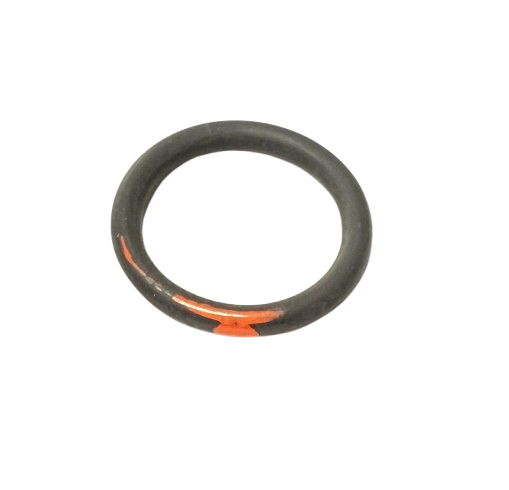

The Graco 122486 O-Ring Packing 0.13 provides reliable sealing and chemical resistance for various Graco sprayers.

The Graco 122486 O-Ring Packing 0.13 ensures precise sealing, high chemical resistance, and extended pump performance. Designed to fit multiple Graco sprayers.

| Part Number | 122486 |

|---|---|

| Type | O-Ring Packing |

| Size | 0.13 |

| Material | Solvent-Resistant Elastomer |

Subscribe to our newsletter to get exclusive discounts and new theme launches right in your inbox.

You may unsubscribe at any moment. For that purpose, please find our contact info in the legal notice.

![]()

![]()

![]()

![]()