Experience unmatched efficiency with the Graco 114805 Jack 1/4 Motor, designed to complement your airless sprayer setup. This precision component delivers consistent performance for demanding coating applications and integrates seamlessly with high-pressure filtration systems. Lightweight construction enhances portability. Engineered for uncompromised flow control, it supports professional-grade finishes, ensuring every spray maintains optimal pressure and uniformity across surfaces and low-maintenance operation. Ideal for contractors seeking top-tier output.

Built on Graco's legacy of durability, the 114805 Jack 1/4 Motor features robust construction to withstand rigorous jobsite environments and intensive use. Its compact footprint and lightweight design simplify installation and maintenance, reducing downtime and boosting productivity. Whether applied in field service or workshop settings, this motor offers reliable power transfer and longevity, making it a versatile solution for professional coatings needs requiring exacting standards. Equip your gear with this essential upgrade.

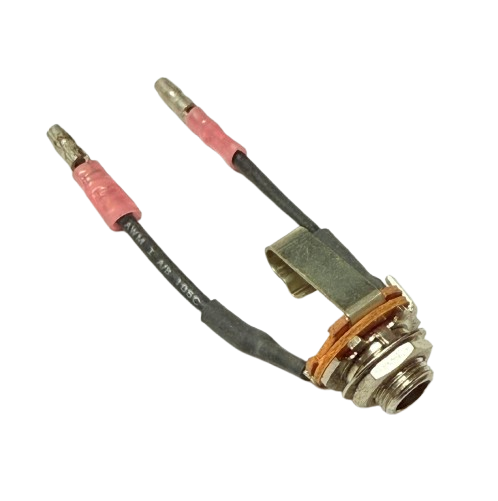

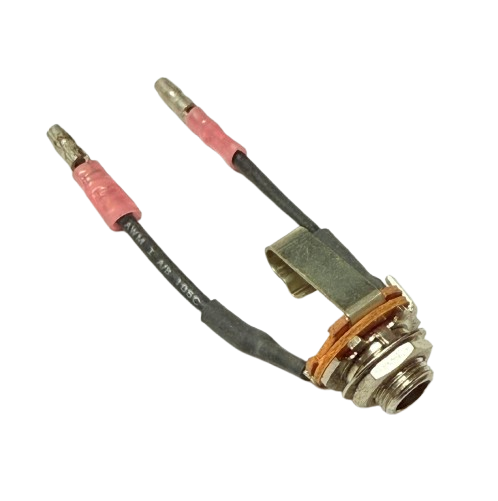

Graco 114805 JACK 1/4 MOTOR is a precision-engineered motor rotor assembly designed to deliver consistent rotational force within compact fluid control systems. Weighing just 0.033 pounds and measuring a mere 1.2" x 0.36" x 0.12", this miniature powerhouse is optimized for integration into high-performance airless sprayer modules and fluid transfer pumps. Featuring a robust laminated steel rotor core, high-grade magnet assemblies, and precision-balance vanes, the 114805 Jack motor ensures uniform torque output at high speeds. Its sealed end shields protect internal components from abrasive particulates, enabling compliance with stringent high-pressure filtration standards. Technicians and engineers value the Jack 1/4 motor for its minimal footprint on pump efficiency and its adaptability to professional coatings delivery systems. The motor’s high-frequency commutation allows smooth ramp-up, reducing overshoot in spray gun actuation. Its standardized mounting dimensions allow seamless retrofitting into legacy systems across automotive refinishing, architectural coatings, and industrial automation platforms.

Design engineers have leveraged the Graco 114805 to achieve compact drive solutions in pneumatic and hydraulic spray equipment. The motor housing is machined from anodized aluminum alloy for superior thermal conduction, while the rotor shaft employs hardened stainless steel to resist torsional fatigue. Integrated ceramic bearings reduce friction and extend operational life, and a nitrile-based seal package is strategically arranged to maintain seal longevity under cyclic loading. The motor’s geometry is tailored to balance magnetic flux density against inertia, yielding optimal torque curves across a broad rpm range. Maintenance protocols recommend filter screens with micron ratings aligned to internal tolerances, preserving high-pressure filtration integrity and maximizing overall system longevity—and improved pump efficiency under varying loads.

The Jack 1/4 motor has been benchmarked to deliver peak torque values exceeding 0.05 Nm at 20 000 rpm, with stall torque margins rated to 0.08 Nm. Dynamometer tests reveal consistent efficiency curves above 75% across a range of operational voltages, ensuring sustained pump efficiency in load-bearing scenarios. Thermal calorimetry confirms that the motor can tolerate ambient temperatures up to 60 °C before requiring active cooling. Endurance trials indicate that the laminated steel stack resists demagnetization, while the composite end caps maintain structural integrity under rapid start-stop cycles. These metrics are critical when deploying the motor in professional coatings metering systems, where precise deposition rates hinge on motor stability.

Constructed with a die-cast aluminum outer shell, the Graco 114805 Jack motor offers exceptional rigidity and lightweight characteristics. The rotor assembly utilizes high-permeability steel laminations to minimize eddy current losses, while neodymium rare-earth magnets provide a high power-density ratio. The stator windings are insulated with class H epoxy varnish, safeguarding against dielectric breakdown at elevated temperatures. Secondary components, such as the ceramic bearing carriers and PTFE-coated shaft seals, contribute to extended maintenance intervals by minimizing metal-to-metal abrasion. The material selection strategy supports both corrosion resistance and chemical compatibility with solvent-based professional coatings, ensuring dependable operation in harsh industrial environments.

When incorporating the Graco 114805 Jack 1/4 motor into system designs, engineers should consider direct coupling to diaphragm or piston pumps for streamlined fluid conveyance. Its quarter-inch keyed shaft interface allows for plug-and-play adapter compatibility, reducing assembly time on production lines. Lubrication requirements are minimal; a periodic application of synthetic oil to accessible bearing points every 500 operating hours typically suffices. Routine inspection of O-ring seals and filter media maintains optimal high-pressure filtration performance, preventing contamination-related failures. By aligning wiring harness gauge selection with the motor’s current draw specifications, designers can uphold voltage stability and preserve motor responsiveness. These best practices collectively enhance pump efficiency, bolster seal longevity, and extend mean time between failure (MTBF) in demanding coating applications.

Subscribe to our newsletter to get exclusive discounts and new theme launches right in your inbox.

You may unsubscribe at any moment. For that purpose, please find our contact info in the legal notice.

![]()

![]()

![]()

![]()